S&S Mono Brake

An innovation from the S&S team in collaboration with Yeti RC. Check out the backstory from Sean below.

S&S

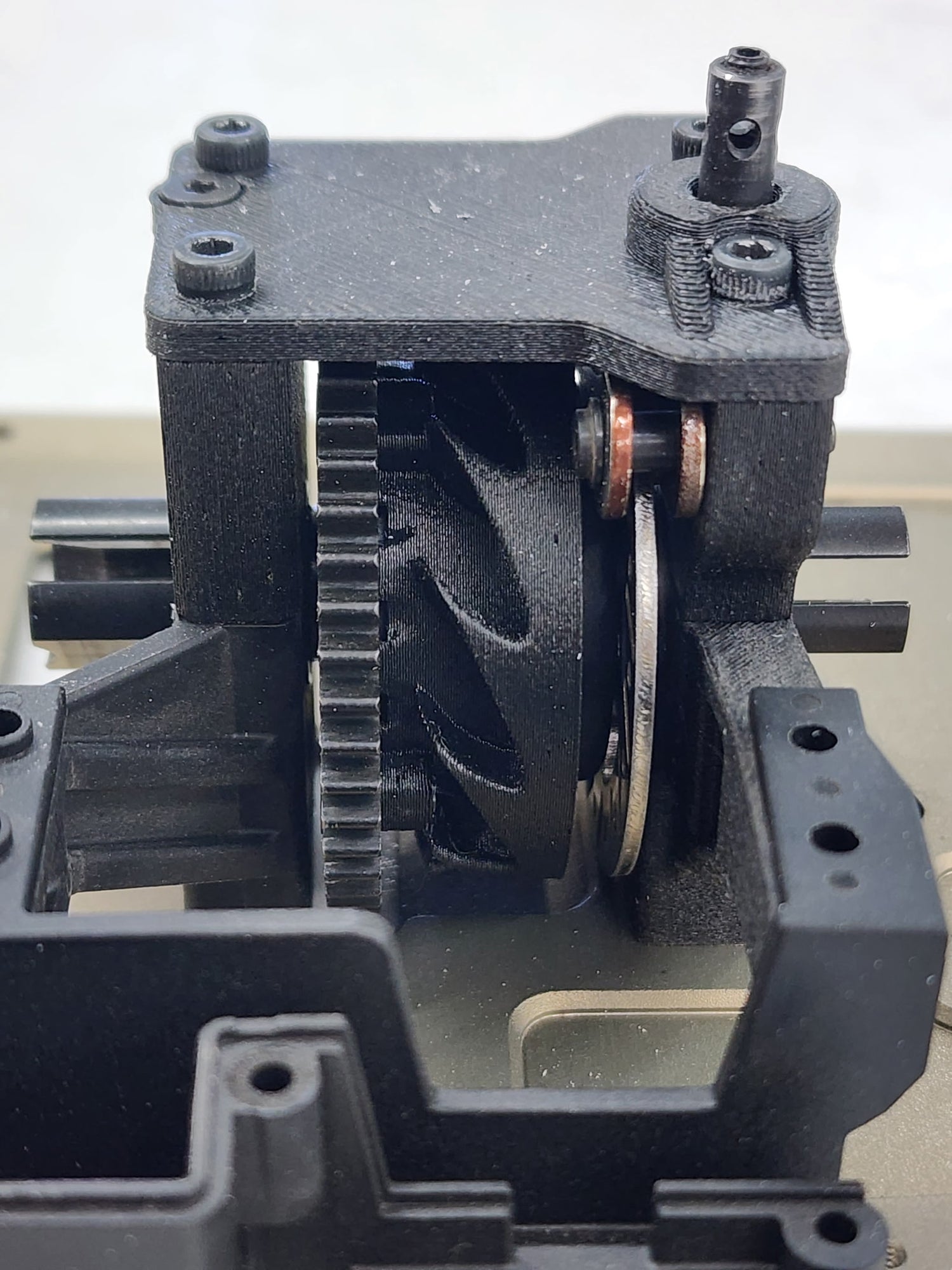

S&S Nitro Mono Brake - Tekno

Why a Mono Brake?

Here is some insight into the S&S Mono Brake™, designed by Seth and Sean (S&S), how we approached this design, and why it’s changed our driving experience.

At 51 years old, with 35 years of racing behind me, I still struggled to set and maintain consistent brake bias—especially as brake components wore in. I often found myself asking my son Seth to adjust my brakes, which made me feel a little like a squid.

So, I challenged Seth to design a single brake mounted to the front of the diff cup—similar to a drive gear. Seth is a very talented designer, and I’m incredibly thankful he brought this idea to life.

What We Discovered in Testing

As a seasoned driver, I often got frustrated when I missed my mark or apex, and I’d instinctively try to drive harder to make up the time. But that only cost me more—adding frustration, slowing my lap times, and, I’ll admit, triggering a bit of "driverstand tourette’s" now and then. With the Mono Brake™ installed, the difference in feel was immediate. I became noticeably more confident during cornering—particularly in situations where I had to brake hard after overdriving a corner.

With a traditional twin-disc system (standard on most cars), hard braking can cause the front tires to lock up and skid, which unsettles the chassis and disconnects it from the racing surface. The Mono Brake™, on the other hand, was more forgiving. It allowed the front tires to keep rolling—almost like ABS—which gave me the ability to steer into the corner and hit my apex, rather than overshooting it.

I also noticed the center diff began transferring braking force to the rear, similar to how it transfers power to the front under acceleration. This kept the rear of the car more stable and even helped initiate rotation into the corner. That meant fewer missed apexes, more consistent lap times, and a lot less frustration.

Material matters. While PLA and PETG are great for prototyping and dialing in fitment, they begin to soften at around 185°F—which is right in the range of rotor temperatures we observed during testing. That made them unsuitable for final parts. With the help of the guys at Yeti RC, we sourced an industrial-grade material with a softening point of 428°F and a heat deflection rating of 381°F— well above anything an RC vehicle will reach. This gave us the confidence to 3D print production-ready components that can reliably withstand the heat, impact, and mechanical stresses of competitive racing.

Cornering and Chassis Stability

Let’s revisit what it means to upset the chassis—specifically, during corner entry.

I've read countless racing books over the years, and they all emphasize the importance of keeping the chassis balanced through both entry and exit. But in practice, many of us tend to focus too much on the exit and forget that what happens before the apex can be just as critical—if not more so.

In a three-diff configuration, your car is constantly working to stay in sync with the racing surface. Power is being transferred front to back and side to side in real time to maintain balance. But the moment you lock or skid the tires under braking—especially during corner entry—you throw that balance off. The differentials now have to “catch up” to each other and re-synchronize. This is what I call a stall.

You’ve probably felt it before: you enter a corner too aggressively, the tires skid, and instead of rotating smoothly, the car hesitates—it doesn’t want to turn. That hesitation is the drivetrain falling out of sync. The diffs aren’t communicating like they were when all four tires were in time with the track surface. If you try to accelerate while this is happening, the car might understeer and push wide, or even snap into oversteer and spin out. Either way, you’re losing rhythm and time.

These stalls create inconsistency, and that’s something every driver—especially non-pros—struggles with. This is where the Mono Brake™ shines.

While no system is perfect, the Mono Brake™ allows the drivetrain to maintain better front-to-rear communication during braking. Unlike a twin-disc setup that often locks the front wheels and causes the diffs to fall out of time, the Mono Brake™ reduces that disruption. The result is a smoother transition into the corner, less instability, and better overall flow through the turn.

Pro drivers are incredibly skilled at managing weight transfer under both braking and acceleration, minimizing how much the chassis gets upset. But let’s be honest—we’re not all pros. The Mono Brake™ gives average racers a tool that helps keep the car settled, lets the diffs stay in sync, and ultimately improves confidence and consistency in corner entry.

Cooling and Component Health

Another benefit we found was from the integrated fan— developed by Yeti RC. During testing, this setup reduced temps by up to 30°F (160°F → 130°F in truck; 130°F → 100°F in buggy). That cooling effect spreads to nearby components: servo, clutch, fuel tank, and even the diff itself.

Traditional twin-disc systems use small rotors that require more force—and generate more heat—to stop the car. That heat transfers to the diff outdrive and directly into the diff fluid. Our Mono Brake™, by contrast, is mounted in a floating design on the plastic of the diff cup, which helps insulate the fluid from heat. The result? Cooler diff temps and extended oil life.

On top of that, our larger rotor requires less force to stop, reducing servo fatigue and increasing consistency.

Is It for Everyone?

Probably not—and that’s perfectly fine. Some drivers prefer the sharp, immediate response of a twin-disc setup. They’re used to tuning their brake bias regularly and might just want to stick with what they know.

For those who struggle with consistency under braking, or want a more forgiving, predictable feel—especially when entering corners—the Mono Brake™ offers a real advantage. It’s a tuning aid that removes variables that get in the way of confident, repeatable laps.

But for me? This has been a game changer. I’ve gained confidence in my car that I didn’t realize I was missing. And I’ll gladly say goodbye to constantly adjusting brake bias.

Tekno for now– More coming soon!

We are actively prototyping and developing the Mono Brake™ system for other manufacturers such as XRay, Mugen Seiki, Sworkz, and others. We are focusing on the nitro platforms first then shifting gears to electrics.

Stay tuned for updates!

The S&S Guarantee

We provide you the highest quality parts and service we deliver.

S&S

S&S Nitro Mono Brake - Tekno